AFM Systems

AFM Accessories

Learning

Contact Us

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Smartphones, electric vehicles, and other technology have made rechargeable Li-ion batteries essential to modern life. Anodes in new, higher-performance battery designs contain silicon (Si) particles and polymer binders, where the binders act to maintain mechanical and electrical integrity despite dramatic volume changes during cycling. Although frictional properties of binders such as interfacial shear strength are critical in this process, they have not been studied extensively.

Researchers at the University of Ulsan addressed this issue by applying nanoscale tribology techniques to five polymer binders: polyacrylic acid (PAA), polyacrylonitrile (PAN), polyvinyl alcohol (PVA), carboxymethyl cellulose (CMC), and polyvinylidene fluoride (PVDF). By performing the experiments with the Si tip of an atomic force microscope (AFM), they could mimic the interactions between Si particles and polymer binders on relevant length scales.

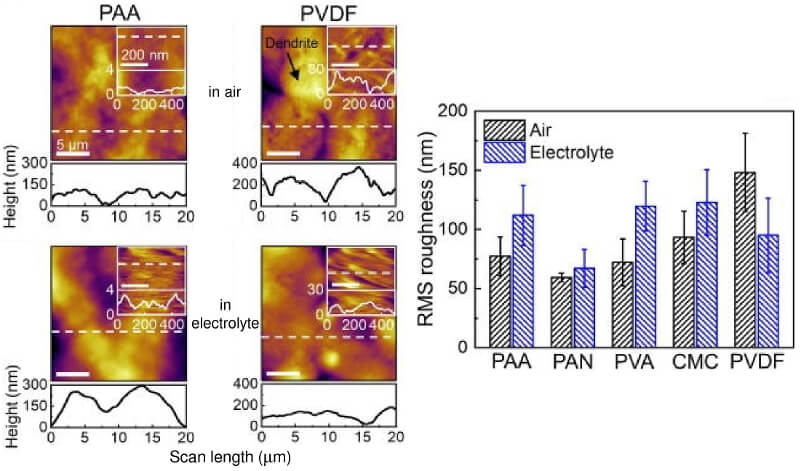

Prior to the tribology experiments, AFM nanoscale morphology images were acquired in both air and LiPF6 electrolyte solution. Surface roughness generally increased in electrolyte, likely due to larger surface asperities from polymer swelling. An observed roughness decrease in PVDF was attributed to structural changes caused by diffusion of the electrolyte solvent into the semicrystalline polymer.

(left) Topography images of polymer binders with line sections corresponding to dashed lines; (right) RMS roughness determined from topography images.

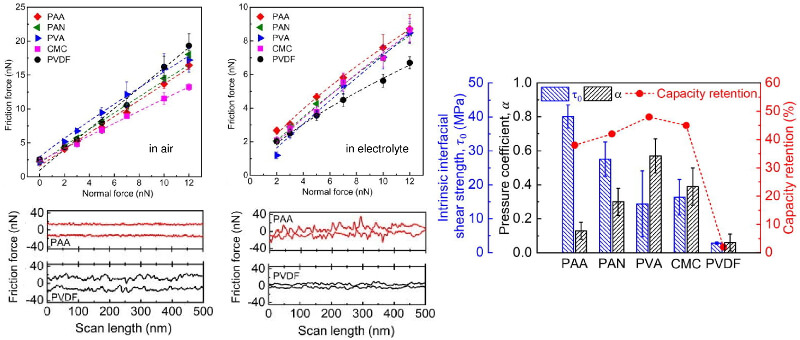

Subsequent measurements showed that friction forces notably decreased in electrolyte but fluctuated more due to the swelling-induced topography changes. Significantly, values for the intrinsic interfacial shear strength τ0 and pressure coefficient α were extracted from the data and found to correlate with anode capacity retention after 50 charge/discharge cycles in electrolyte.

The findings suggest that interfacial shear strength properties could be better metrics of binder performance than other mechanical and adhesion properties. Ultimately, the deeper understanding of frictional properties of polymer binders in electrolytes gained from this work may help improve the mechanical integrity of Si anodes in batteries, supercapacitors, and other energy storage devices.

(left, top) Measured friction force (symbols) and fit to model (dashed lines); (left, bottom) Example friction loops; (right) Capacity retention and τ and α0 values determined from fits to friction data.

Instrument used

The experiment was performed using an MFP-3D with a Closed Fluid Cell accessory. The success of this experiment was dependent on the MFP-3D’s ability to make quantitative friction loop measurements and take high-resolution images in air and solution.

The closed fluid cell used in this experiment allow measurements in air and solution without disturbing the sample or the need to move the cantilever. This allows for direct comparisons to be made at the same location, minimizing variations due to sample heterogeneity or roughness.

The MFP-3D was designed specifically for optimal force measurements and has several advantages over other AFMs when making these measurements. For example, the optical beam deflection components move together, eliminating large relative changes in the deflection path that results in measurement errors. This ensures only the cantilever deflection is being measured, and that the optical lever sensitivity stays constant throughout the force measurement. The detection laser is also optimized, with an 860 nm super luminescent diode (SLD), which minimizes optical interference associated with regular laser diodes. These features let the MFP-3D make very accurate quantitative displacement and force measurements.

Another advantage of the MFP-3D’s over many AFMs is the complete decoupling of the XY piezo scanner from the Z scanner. This ensures that rastering, or lateral motions, are very flat. Tube scanners that incorporate XY- and Z-motions together are prone to bow artifacts whether imaging or doing friction loops.

Finally, Asylum Research is the only company to use linear variable differential transformers (LVDTs) as position sensors in the scanners. Compared to more commonly used capacitive sensors and strain gauge sensors, LVDTs offer lower noise, lower drift, inherently linear response, and never need to be recalibrated. The low sensor noise and linear response enable the MFP-3D to take high resolution images with highly accurate metrology.

The MFP-3D’s high-resolution imaging capabilities, accurate spectroscopy measurements and support for a wide range of accessories make it one of the most versatile and powerful AFMs on the market. Whether its electrical, thermal, magnetic, or nanomechanical data; working in solution, or controlling the temperature the MFP-3D is uniquely suited for the task.

Related Applications: Energy Storage, Polymers

Techniques used

Polymer films deposited on copper substrates were examined with lateral force microscopy (LFM) techniques on an MFP-3D AFM. A Closed Fluid Cell was used to completely immerse the sample and cantilever in electrolyte (LiPF6 dissolved in 1:1:1 ethylene carbonate:dimethyl carbonate:ethyl methyl carbonate). Calibration of the cantilever’s flexural and torsional spring constants and horizontal and vertical deflection sensitivities enabled quantitative measurements of absolute forces. Values for the work of adhesion and tip radius needed for model fitting were obtained from AFM force curves and scanning electron microscopy (SEM), respectively. The experiments demonstrate the MFP-3D’s capabilities for accurate, quantitative measurements at an affordable price.

Citation: Quang Dang Nguyen and Koo-Hyun Chung, Frictional properties of polymer binders for Li-ion batteries. Appl. Phys. Lett. 116, 061604 (2020). https://doi.org/10.1063/1.5141495

Note: The data shown here are reused under fair use from the original article, which can be accessed through the article link above.