AFM Systems

AFM Accessories

Learning

Contact Us

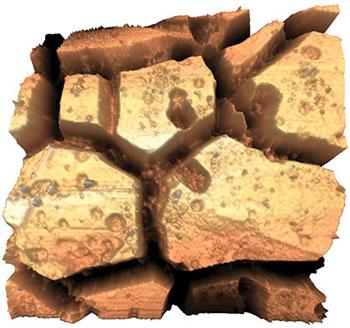

Atomic force microscopy allows researchers to characterize the topography and mechanical properties of biomaterials. The AFM can accurately measure surface roughness and microstructure as a function of composition and processing variables. Biomaterials can also be inspected after in vitro testing or after explantation to assess changes in surface features. A wide range of AFM techniques can be applied to measure the stiffness, moduli, and dissipation of biomaterials.

Ask an AFM expert for more information"Silk protein nanowires patterned using electron beam lithography," R. K. Pal, and V. K. Yadavalli, Nanotechnology 29, 335301 (2018). https://doi.org/10.1088/1361-6528/aac855

"Type I collagen from jellyfish Catostylus mosaicus for biomaterial applications," Z. Rastian, S. Pütz, Y. J. Wang, S. Kumar, F. Fleissner, T. Weidner, and S. H. Parekh, ACS Biomater. Sci. Eng. 4, 2115 (2018). https://doi.org/10.1021/acsbiomaterials.7b00979

"Mutable polyelectrolyte tube arrays: mesoscale modeling and lateral force microscopy," S. W. Cranford, L. Han, C. Ortiz, and M. J. Buehler, Soft Matter 13, 5543 (2017). https://doi.org/10.1039/c7sm00864c

"Engineered phage nanofibers induce angiogenesis," S. Y. Yoo, K. R. Shrestha, S. N. Jeong, J. I. Kang, and S. W. Lee, Nanoscale 9, 17109 (2017). https://doi.org/10.1039/c7nr03332j

"3D bioprinted graphene oxide-incorporated matrix for promoting chondrogenic differentiation of human bone marrow mesenchymal stem cells," X. Zhou, M. Nowicki, H. Cui, W. Zhu, X. Fang, S. Miao, S. J. Lee, M. Keidar, and L. G. Zhang, Carbon 116, 615 (2017). https://doi.org/10.1016/j.carbon.2017.02.049

"The structure and mechanical properties of articular cartilage are highly resilient towards transient dehydration," K. Boettcher, S. Kienle, J. Nachtsheim, R. Burgkart, T. Hugel, and O. Lieleg, Acta Biomater. 29, 180 (2016). https://doi.org/10.1016/j.actbio.2015.09.034

"Heterogeneous silicon mesostructures for lipid-supported bioelectric interfaces," Y. Jiang, J. L. Carvalho-de-Souza, R. C. Wong, Z. Luo, D. Isheim, X. Zuo, A. W. Nicholls, I. W. Jung, J. Yue, D. J. Liu, and Y. Wang, Nat. Mater. 15, 1023 (2016). https://doi.org/10.1038/nmat4673

"Regenerated silk materials for functionalized silk orthopedic devices by mimicking natural processing," C. Li, B. Hotz, S. Ling, J. Guo, D. S. Haas, B. Marelli, F. Omenetto, S. J. Lin, and D. L. Kaplan, Biomaterials 110, 24 (2016). https://doi.org/10.1016/j.biomaterials.2016.09.014

"Modulation of protein fouling and interfacial properties at carbon surfaces via immobilization of glycans using aryldiazonium chemistry," F. Zen, M. D. Angione, J. A. Behan, R. J. Cullen, T. Duff, J. M. Vasconcelos, E. M. Scanlan, and P. E. Colavita, Sci. Rep. 6, 24840 (2016). https://doi.org/10.1038/srep24840

"Nanomechanics of cells and biomaterials studied by atomic force microscopy," J. I. Kilpatrick, I. Revenko, and B. J. Rodriguez, Adv. Healthcare Mater. 4, 2456 (2015). https://doi.org/10.1002/adhm.201500229

"The preparation and characterization of polycaprolactone/graphene oxide biocomposite nanofiber scaffolds and their application for directing cell behaviors," J. Song, H. Gao, G. Zhu, X. Cao, X. Shi, and Y. Wang, Carbon 95, 1039 (2015). https://doi.org/10.1016/j.carbon.2015.09.011

"Application of layer-by-layer coatings to tissue scaffolds—development of an angiogenic biomaterial," C. D. Easton, A. J. Bullock, G. Gigliobianco, S. L. McArthur, and S. MacNeil, J. Mater. Chem. B 2, 5558 (2014). https://doi.org/10.1039/c4tb00448e

"Chirality effects at each amino acid position on tripeptide self-assembly into hydrogel biomaterials," S. Marchesan, C. D. Easton, K. E. Styan, L. J. Waddington, F. Kushkaki, L. Goodall, K. M. McLean, J. S. Forsythe, and P. G. Hartley, Nanoscale 6, 5172 (2014). https://doi.org/10.1039/c3nr06752a

"Load-bearing in cortical bone microstructure: Selective stiffening and heterogeneous strain distribution at the lamellar level," O. L. Katsamenis, H. M. Chong, O. G. Andriotis, and P. J. Thurner, J. Mech. Behav. Biomed. Mater. 17, 152 (2013). https://doi.org/10.1016/j.jmbbm.2012.08.016

"Nanomechanical mapping of the osteochondral interface with contact resonance force microscopy and nanoindentation," S. E. Campbell, V. L. Ferguson, and D. C. Hurley, Acta Biomater. 8, 4389 (2012). https://doi.org/10.1016/j.actbio.2012.07.042

"Dilatational band formation in bone," A. A. Poundarik, T. Diab, G. E. Sroga, A. Ural, A. L. Boskey, C. M. Gundberg, and D. Vashishth, Proc. Natl. Acad. Sci. U.S.A. 109, 19178 (2012). https://doi.org/10.1073/pnas.1201513109

"Immunofluorescence-guided atomic force microscopy to measure the micromechanical properties of the pericellular matrix of porcine articular cartilage," R. E. Wilusz, L. E. DeFrate, and F. Guilak, J. Royal Soc. Interface 9, 2997 (2012). https://doi.org/10.1098/rsif.2012.0314

"Diameter of titanium nanotubes influences anti-bacterial efficacy," B. Ercan, E. Taylor, E. Alpaslan, and T. J. Webster, Nanotechnology 22, 295102 (2011). https://doi.org/10.1088/0957-4484/22/29/295102

"Experimental evidence for interfacial biochemical bonding in osseointegrated titanium implants," Y.-T. Sul, D. H. Kwon, B.-S. Kang, S.-J. Oh, and C. Johansson, Clin. Oral Implants Res. 24, 8 (2011). https://doi.org/10.1111/j.1600-0501.2011.02355.x

"Physical surface and electromechanical properties of doped polypyrrole biomaterials," A. Gelmi, M. J. Higgins, and G. G. Wallace, Biomaterials 31, 1974 (2010). https://doi.org/10.1016/j.biomaterials.2009.11.040

"Autonomic self‐healing of hydrogel thin films," A. B. South and L. A. Lyon, Angew. Chem. Int. Ed. 49, 767 (2010). https://doi.org/10.1002/anie.200906040

"Titanium implant surface modification by cathodic reduction in hydrofluoric acid: Surface characterization and in vivo performance," S. F. Lamolle, M. Monjo, S. P. Lyngstadaas, J. E. Ellingsen, and H J. Haugen, J. Biomed. Mater. Res. 88A, 581 (2009). https://doi.org/10.1002/jbm.a.31898

"Hydride formation on titanium surfaces by cathodic polarization," K. Videm, S. Lamolle, M. Monjo, J. E. Ellingsen, S. P. Lyngstadaas, and H J. Haugen, Appl. Surf. Sci. 255, 3011 (2008). https://doi.org/10.1016/j.apsusc.2008.08.090

"Protective coatings on extensible biofibres," N. Holten-Andersen, G. E. Fantner, S. Hohlbauch, J. H. Waite, and F. W. Zok, Nat. Mater. 6, 669 (2007). https://doi.org/10.1038/nmat1956

"Nanoscale heterogeneity promotes energy dissipation in bone," K. Tai, M. Dao, S. Suresh, A. Palazoglu, and C. Ortiz, Nat. Mater. 6, 454 (2007). https://doi.org/10.1038/nmat1911