AFM Systems

AFM Accessories

Learning

Contact Us

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

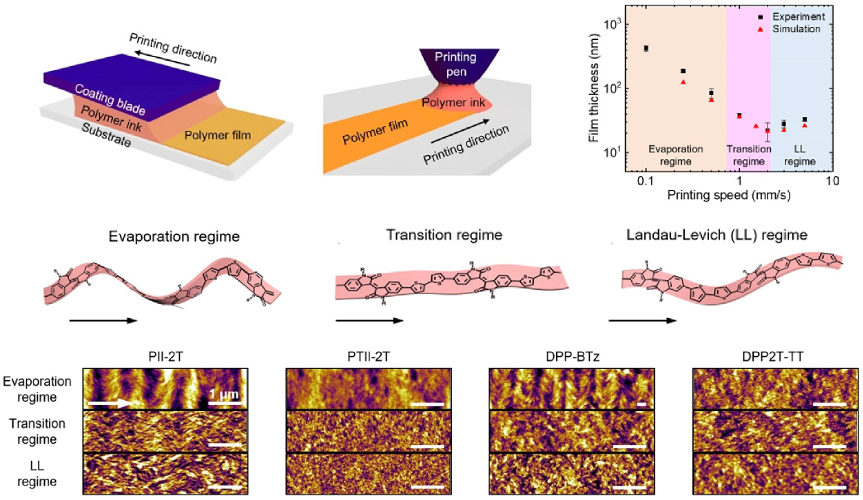

Researchers used tapping mode AFM to understand how conjugated polymers could be stretched and flattened during flow printing to improve their electrical and optical properties.

The unique ability of conjugated polymers to carry charge along a backbone chain could hold the key to faster and cheaper electronic devices. The shape of these polymers strongly affects their electrical properties, with flat, untwisted backbones giving better performance. However, no easy way was known to achieve the desired planarity.

A team led by engineers at the University of Illinois has demonstrated how flow-directed assembly can remedy this situation. Together with researchers at Purdue University, University of Mons, and Inha University, they discovered a third flow regime during meniscus-guided printing that yields improved electrical and optical properties.

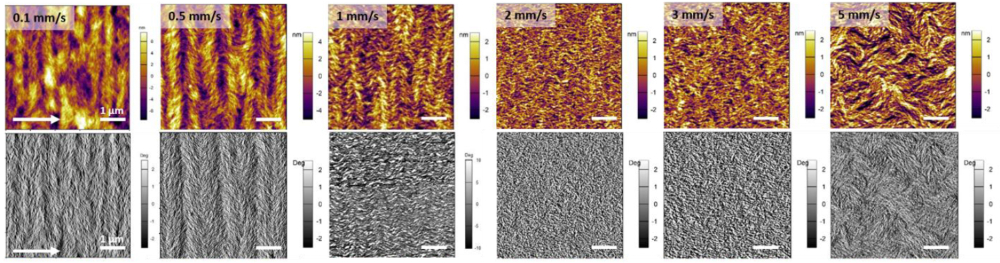

Varying printing settings including speed let them tune polymer morphology and thus enhance charge mobility. AFM nanoscale imaging along with other experimental tools and simulations revealed relations between processing conditions, polymer structure, and electrical performance. In particular, AFM images of topography and tapping-mode phase were used to evaluate how printing speed affected film thickness and fiber alignment.

The results indicate an effective way to control assembly of conjugated polymers and could lead to next-generation technology such as faster biomedical devices and flexible electronics.

Tapping mode images of topography and phase were acquired to characterize the thickness and morphology of films flow-printed at different speeds. The Cypher AFM’s low noise floor enabled accurate measurements of film thickness for comparison to simulation results, while its high spatial resolution allowed clear visualization of highly aligned crystallized domains. Phase images that had been filtered to enhance contrast gave detailed information on fiber alignment.

Citation: K. Park, J. Kwok, R. Dilmurat et al., Tuning conformation, assembly, and charge transport properties of conjugated polymers by printing flow. Sci. Adv. 5, eaaw7757 (2019). https://advances.sciencemag.org/content/5/8/eaaw7757

Note: The original article featured above was published as Open Access. The data shown here are reused under fair use from the original article, which can be accessed through the article link above.