AFM Systems

AFM Accessories

Learning

Contact Us

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

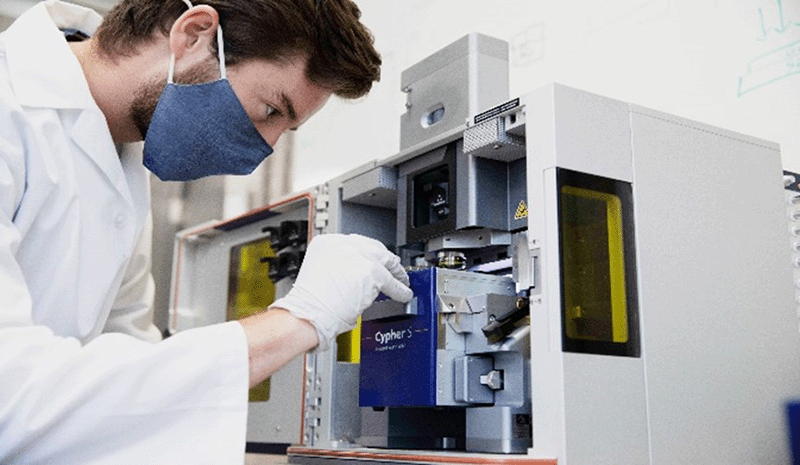

Nanomaterials research often involves correlating structure and function on the atomic scale, and the AFM offers unique capabilities for obtaining this data. For example, Peter Serles, PhD candidate in the lab of Professor Tobin Filleter (University of Toronto), has used both the Cypher S and MFP‑3D Origin AFMs to analyze the frictional properties of MoS2 coatings (widely used as solid lubricants) and to conduct one of the first studies of frictional properties in a non-van der Waals 2D material – magnetene. This material has potential in the development of advanced lubricants.

|

“Our Cypher and MFP-3D AFMs enable both routine AND advanced characterization. Switching between modes is easy, and there’s no compromise in speed, resolution, or sensitivity.” — Peter Serles, PhD candidate in the lab of Professor Tobin Filleter, |

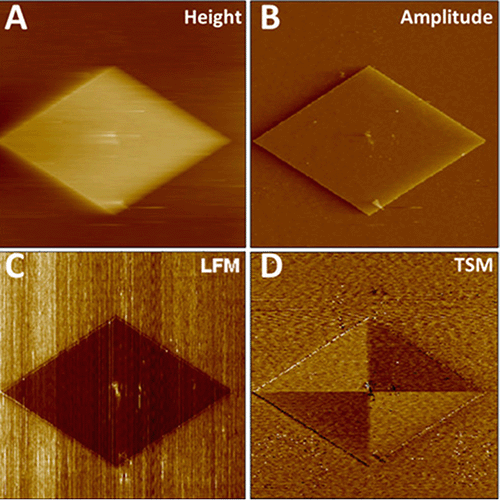

The work on magnetene included quantitative friction measurements made with the Cypher and MFP-3D in Lateral Force Microscopy (LFM) mode with calibration of the cantilever torsional spring constant [i]. In another study, sectorization of polymer alignment within single crystals of polyethylene was mapped using a novel, recently developed measurement technique called Transverse Shear Microscopy (TSM). Here the tip/sample scan motion is performed along the long axis of the cantilever [ii].

To quantify the strength and mechanical failure characteristics of MoS2 coatings, the group created tiny micro-beams from the material. Then they used the MFP-3D to perform quantitative static deflection mode measurements along the length of the beam to quantify the stiffness and strength [iii].

In yet another study, they examined how fluorinating hexagonal boron nitride (hBN) led to a correlated decrease in both bandgap and friction. The friction was measured using lateral force microscopy (LFM) and the bandgap was determined using conductive AFM (cAFM) measurements in ORCA mode [iv].

Peter notes, “Typical of nanomaterials research, we’re looking at both morphology and a wide range of materials characteristics: from electrical and magnetic properties to physical attributes like friction and strength/stress parameters (e.g., Young’s modulus.) So, we need an AFM that offers the flexibility to easily perform many different types of measurement modes.

“Our Cypher and MFP-3D AFM’s enable both routine AND advanced characterization. Switching between modes is easy, and there’s no compromise in speed, resolution, or sensitivity. Also, for some of our most challenging work, we were greatly aided by the open-source software of the Asylum Research AFM.”

|

Mapping single crystals of polyethylene. Only the novel TSM method can image the sectorization. |

[i] P. Serles et al., Friction of magnetene, a non–van der Waals 2D material, Science Advances, 2021, 7 (47). https://doi.org/10.1126/sciadv.abk2041

[ii] M. Hamidinejad et al., Sectorization of Macromolecular Single Crystals Unveiled by Probing Shear Anisotropy, ACS Macro Letters, 2022, 11, 1, 53-59. https://doi.org/10.1021/acsmacrolett.1c00603

[iii] G. Colas et al., Strength measurement and rupture mechanisms of a micron thick nanocrystalline MoS2 coating using AFM based micro-bending tests, Journal of the Mechanics and Physics of Solids, 2019, 128, 151-161, https://doi.org/10.1016/j.jmps.2019.04.007

[iv] A. Meiyazhagan et al., Gas-Phase Fluorination of Hexagonal Boron Nitride, Advanced Materials, 33 (52), 2106084. https://doi.org/10.1002/adma.202106084

Author: Asylum Research

Category: Case Study