AFM Systems

AFM Accessories

Learning

Contact Us

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

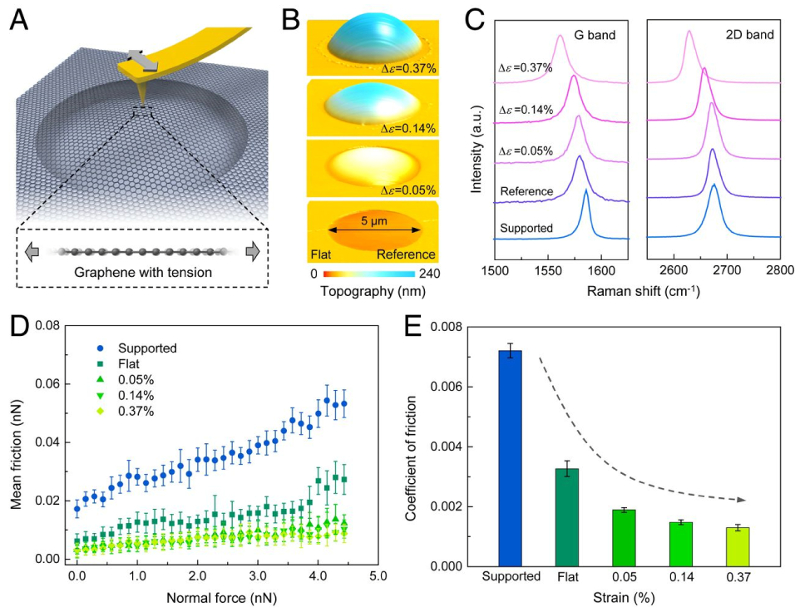

Nanotribology experiments on pressurized graphene sheets showed its already low friction could be further reduced by applying tensile strain in a controlled, reversible process.

The ability to actively control—and preferably minimize—friction has been a longstanding goal to benefit technology ranging from cars to MEMS devices. 2D materials such as graphene, which exhibit ultra-low friction (superlubricity), offer exciting possibilities for realizing this dream.

The ability to actively control—and preferably minimize—friction has been a longstanding goal to benefit technology ranging from cars to MEMS devices. 2D materials such as graphene, which exhibit ultra-low friction (superlubricity), offer exciting possibilities for realizing this dream.

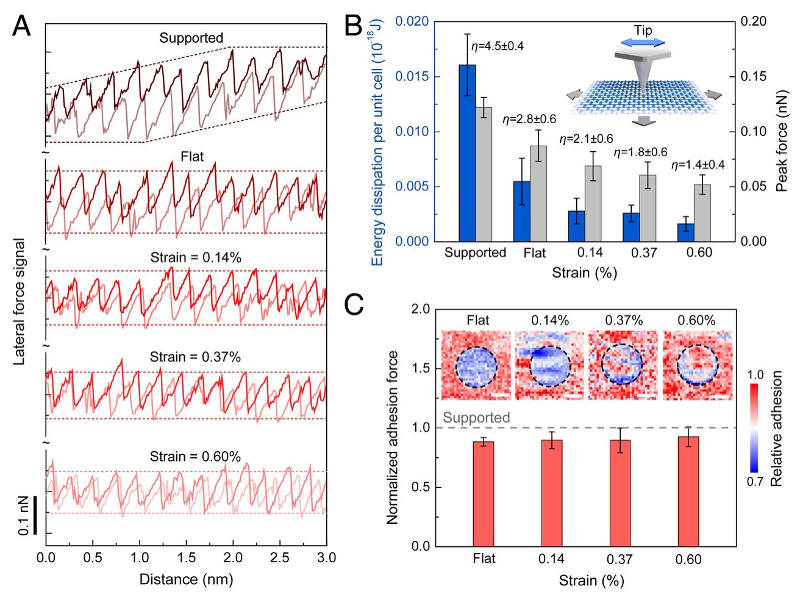

Researchers at Tsinghua University and other Chinese institutes demonstrated progress in this area using pressurized graphene bubbles stretched over holes in a substrate. They showed that simply pulling the graphene sheet lowered its friction; further, they could control the friction in a reversible way by adjusting the tensile strain. Data from AFM friction and adhesion experiments supported the predictions of molecular dynamics simulations, which indicated the effect arose from strain-induced changes in the atomic-scale tip-sample contact.

From a fundamental standpoint, the results provide insight into the differences in frictional behavior between 2D and 3D materials. Moreover, they offer a practical strategy for tuning friction that could be used for many new devices with dynamically-configurable sliding interfaces.

Nanoscale friction experiments were performed in lateral force microscopy (LFM) mode on a Cypher AFM. Values for the coefficient of friction were determined by measuring friction force versus normal load. The high force sensitivity and low noise floor of Cypher AFMs ensured precise measurements even in this ultralow friction regime. Atomic-scale stick-slip curves were also obtained with LFM and used to calculate energy dissipation and peak lateral force. Topography imaging of bubble height and adhesion mapping with force curves provided additional insight.

Citation: S. Zhang, Y. Hou, S. Li et al., Tuning friction to a superlubric state via in-plane straining. Proc. Natl. Acad. Sci. U.S.A. 116, 24452 (2019). https://doi.org/10.1073/pnas.1907947116

Note: The data shown here are reused under fair use from the original article, which can be accessed through the article link above.