AFM Systems

AFM Accessories

Learning

Contact Us

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Areas of sliding contact between load-bearing surfaces such as gears, bearings, and pistons are the most likely sites of failure in mechanical systems [i]. These interfaces are typically under high mechanical stress and experience both material (wear) and energy (friction) dissipation, which leads to waste, and, worse, to catastrophic failure.

Understanding what goes on in these “tribo-” (or “rubbing”) interfaces is critical in developing new materials, such as lubricants and additives, that ameliorate losses and minimize failure. Friction and wear are serious economic problems, contributing more than one fifth to global energy consumption [ii]. However, investigating their mechanisms, especially at the microscopic level, is very challenging, as these phenomena are literally hidden between the contacting bodies. Ay, there’s the rub, so to speak.

Since the 1990s, AFMs have become staple tools in tribological research, whether for visualizing the texture of wear tracks after sliding experiments or for measuring friction forces at the nanoscale [iii]. The AFM tip represents a model single asperity contact, and sliding is typically under boundary conditions, where friction is highest. The AFM optical detection system monitors both the normal motion of the cantilever spring, which represents the normal load, as well as the torsional motion, which represents the frictional force. One can thus measure friction response at a specific load, or, even better, the dependence of friction on load, which is essentially the coefficient in Amonton’s law.

In the example below, we take a look at tribofilms formed on a hard, higher-friction surface after 1h versus 6h of sliding experiments with a reciprocating tribometer. Tribofilms are thin coatings formed during the sliding of contacting surfaces that can profoundly affect their friction and wear behavior [iv]. The formation of tribofilms is typically complex and often poorly understood. It involves the transformation of materials from contacting surfaces, or their surrounding environment (e.g., lubricants and additives) and is induced by mechanical, chemical, and thermal reactions. Once formed and adhered to the surface, these tribofilms can dominate the tribological performance of the sliding contact. They are thus important targets of investigation and engineering.

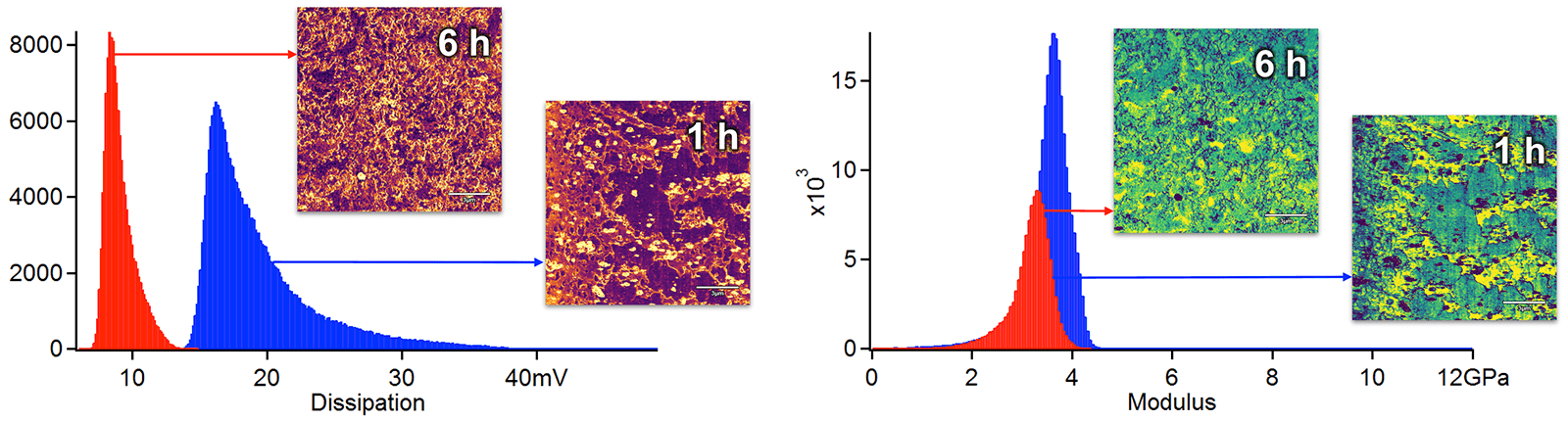

In addition to mapping out friction response via lateral force microscopy, as described above, other techniques can be employed to gain insight on the nanomechanics of tribofilms. For example, AM-FM Viscoelastic Mapping Mode, a technique unique to Asylum Research, yields both modulus and dissipation maps, while simultaneously imaging the sample in tapping mode [v]. These represent elastic response and viscous (and adhesive) damping—mechanical properties critical to know about polymer films.

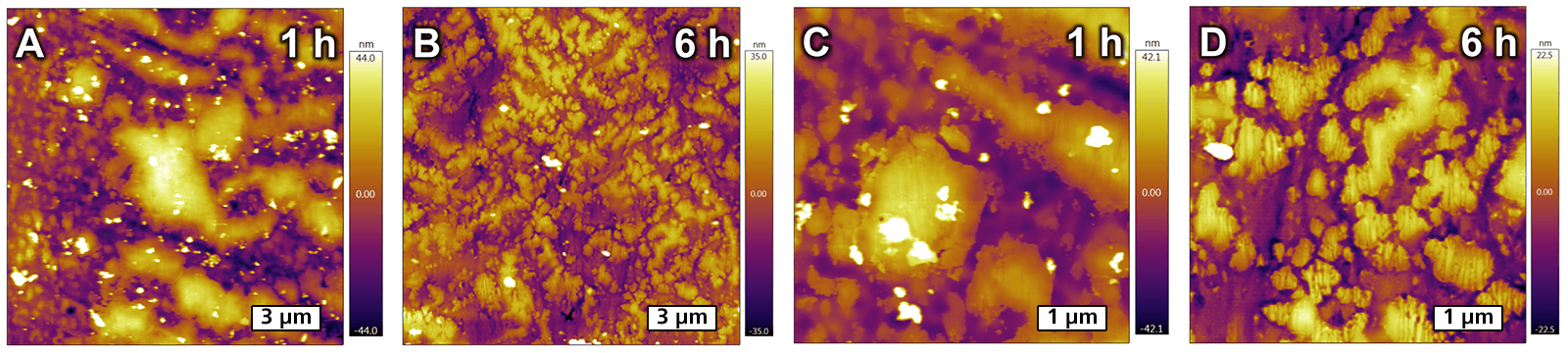

Figure 1. Evolution of tribofilm texture over time. Topographical images show how the texture of the tribofilm changes when the duration of reciprocal sliding increases from 1 h to 6 h. (A & C) After 1 h of sliding a patchy film develops with very uneven patch sizes. (B & D) After 6 h of sliding, we still see patches, but they are smaller, more monodisperse in size, and more evenly distributed on the surface.

Figure 2. Evolution of tribofilm dissipation and modulus over time. Dissipation and modulus maps were obtained using AM-FM Viscoelastic Mapping Mode. (Left) Dissipation histograms show that the film subjected to 6 h of reciprocal sliding exhibits lower damping behavior (about half as much as the film at 1 hour) as well as a more homogenous distribution. (Right) The modulus also shifts slightly to lower values for the film subjected to 6 h of reciprocal sliding compared to the film at 1 h.

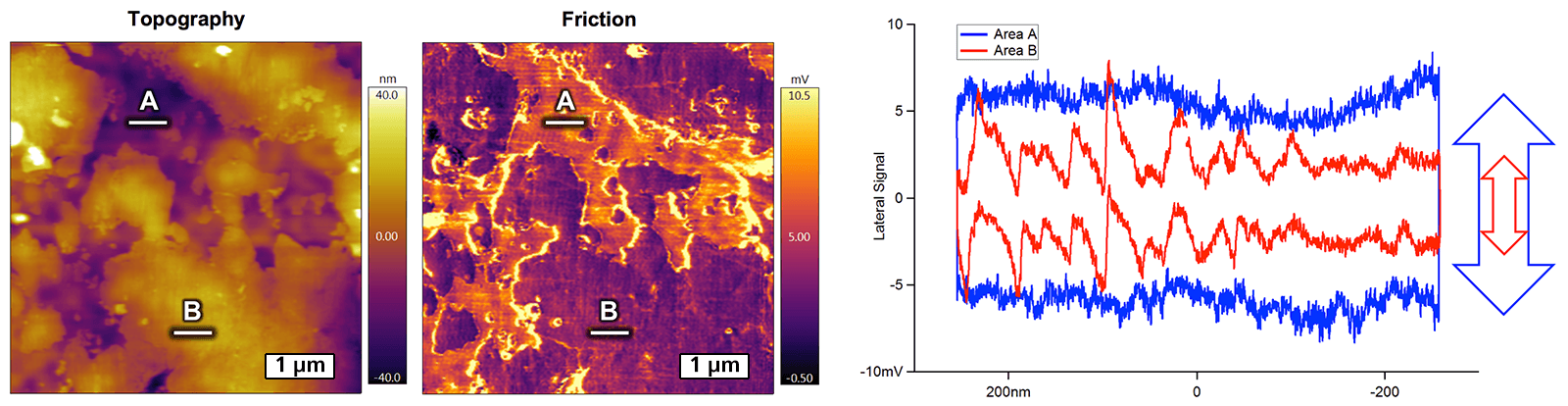

Figure 3. Topographic and friction images and friction loops for the tribofilm after 1 h of reciprocal sliding. Comparison of topography and friction images reveals lower friction response on the raised tribofilm patches (i.e., plateaus) versus the valleys. This shows that the valleys have different material properties (and perhaps composition) compared to the top of the film. Friction loops were obtained on 500 nm segments of the different areas, as indicated on the images. Valleys such as area A show a wider friction loop, indicating higher friction, while plateaus such as area B show a tighter friction loop (lower friction) but with significant stick-slip sliding, as indicated by the saw tooth pattern.

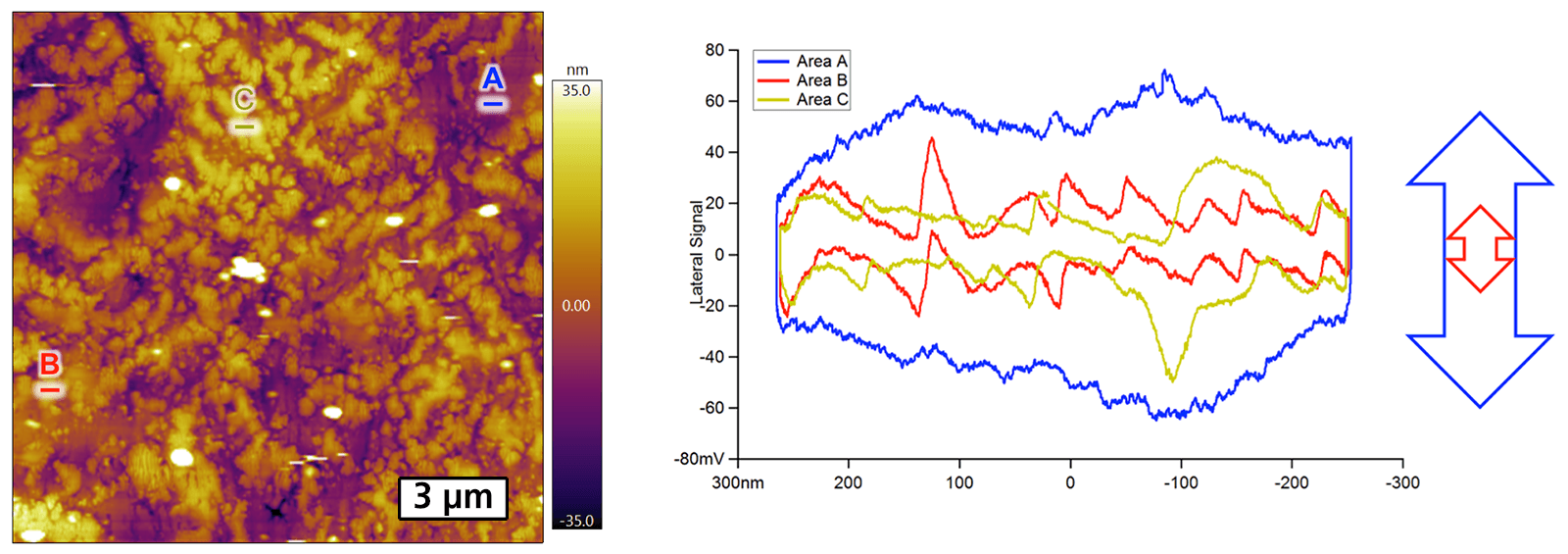

Figure 4. Friction loops for the tribofilm after 6 h of reciprocal sliding. Like the film subjected to wear for only 1 hour, the friction loop data for the 6 hour film indicates higher friction in the valleys, though the friction is more irregular. The plateau areas similarly indicate lower friction and more jagged sliding behavior, again consistent with the 1 h film. Note that the same tip mounting and normal loads were used for both the 1 h and 6 h tribofilm measurements so that the magnitudes of the lateral signal can more or less be compared. From this, we can see that the width of the friction loop increased eightfold on the tribofilm patches or plateaus, and eight- to twelvefold in the valleys.

[i] Williams, John. Engineering tribology. Oxford University Press, 1994.

[ii] Holmberg, Kenneth, and Ali Erdemir. "Influence of tribology on global energy consumption, costs and emissions." Friction 5, no. 3 (2017): 263-284.

[iii] Carpick, Robert W., and Miquel Salmeron. "Scratching the surface: fundamental investigations of tribology with atomic force microscopy." Chemical reviews 97, no. 4 (1997): 1163-1194.

[iv] Luo, Quanshun. "Tribofilms in solid lubricants." Encyclopedia of Tribology (2013): 3760-3767.

[v] Kocun, Marta, Aleksander Labuda, Waiman Meinhold, Irene Revenko, and Roger Proksch. "Fast, high resolution, and wide modulus range nanomechanical mapping with bimodal tapping mode." ACS nano 11, no. 10 (2017): 10097-10105.

Samples courtesy of Dr. Lucija Coga, Faculty of Mechanical Engineering, Laboratory for Tribology and Interface Nanotechnology, Ljubljana, Slovenia.

Date: September 12. 2018

Author: Dr. Ted Limpoco, Asylum Research

Category: Application Note