AFM Systems

AFM Accessories

Learning

Contact Us

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Chinese researchers made ferroelectric random access memory (FeRAM) using self-assembled P(VDF-TrFE) copolymers. Nanoscale characterization of a prototype device helped confirm the device’s enhanced thermal stability and storage density of ~60 GB/in2.

The high storage density and low power consumption of FeRAM devices make them attractive for a range of data storage applications. Flexible FeRAM could further extend this range, but inorganic ferroelectrics are typically too brittle and organic ferroelectrics have limited thermal stability.

Researchers at Tsinghua University fabricated a prototype FeRAM device from the organic ferroelectric poly(vinylidene fluoride-co-trifluoroethylene) [P(VDF-TrFE)]. They used low-temperature self-assembly techniques to create an aligned array of edge-on nanolamellae.

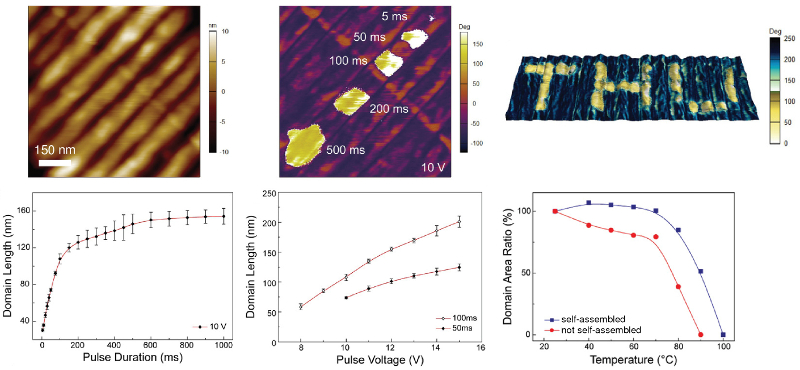

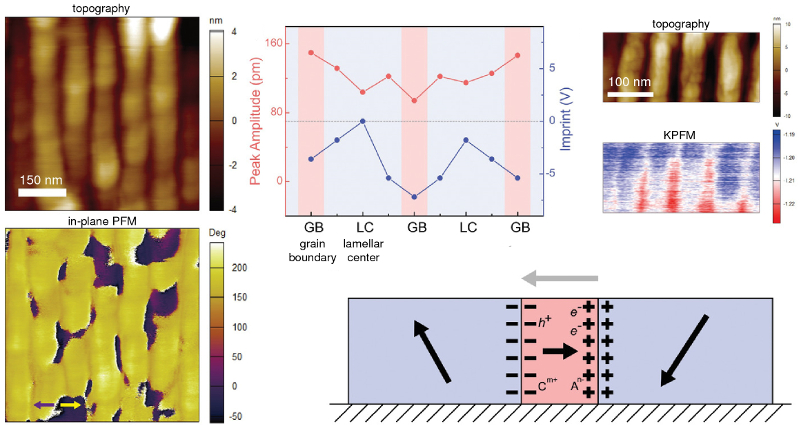

Nanoscale electromechanical experiments demonstrated domain switching of ‘bits’ as small as 100x100 nm2, indicating storage densities of ~60 GB/in2. Moreover, the written patterns appeared virtually unchanged after a month. Devices with self-assembled films also remained stable to higher temperatures than ones with spin-coated films. The behavior was explained by pinning effects at grain boundaries between adjacent lamellae.

The results demonstrate a new strategy for creating more robust, flexible ferroelectric memory devices. In addition, they illustrate the potential of self-assembly for creating functional nanomaterials.

All AFM experiments were performed on an MFP-3D AFM. Nanoscale topography was measured in contact mode, while electromechanical behavior was evaluated with piezoresponse force microscopy (PFM) techniques and a conducting tip. These experiments used the MFP-3D’s built-in software to apply voltage pulses of varying duration and amplitude to the tip and then sense the sample’s in-plane or out-of-plane response. Temperature-dependent PFM measurements were made using a heated sample stage for precise, sensitive temperature control. Additionally, surface potential images were acquired with Kelvin probe force microscopy (KFPM) to better understand grain boundary effects. Combined, the measurements illustrate the power of MFP-3D AFMs for experimental flexibility without sacrificing ease of use.

Citation: M. Guo, J. Jiang, J. Qiang et al., Flexible robust and high-density FeRAM from array of organic ferroelectric nano-lamellae by self-assembly. Adv. Sci. 6, 1801931 (2019). https://doi.org/10.1002/advs.201801931

Note: The original article featured above was published as Open Access under a Creative Commons license. The data shown here are reused under fair use of the original article, which can be accessed through the article link above.