AFM Systems

AFM Accessories

Learning

Contact Us

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

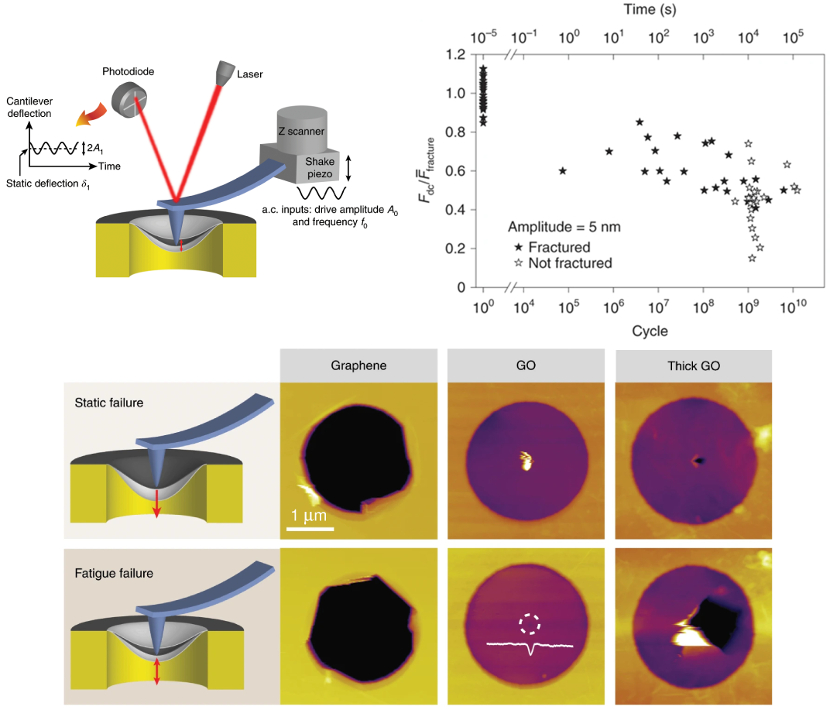

Researchers performed mechanical fatigue tests on graphene and graphene oxide by cyclic loading with an AFM tip. The tests showed a fatigue life for graphene of over one billion cycles, which is higher than any other material reported.

The ability of 2D materials such as graphene to withstand very high stresses without breaking make them enticing prospects for flexible electronics, nanocomposite materials, and other applications. Another key metric for these applications is fatigue resistance—the ability to withstand small, repetitive loading. However, the long-term mechanical reliability of atomically thin materials is not well understood.

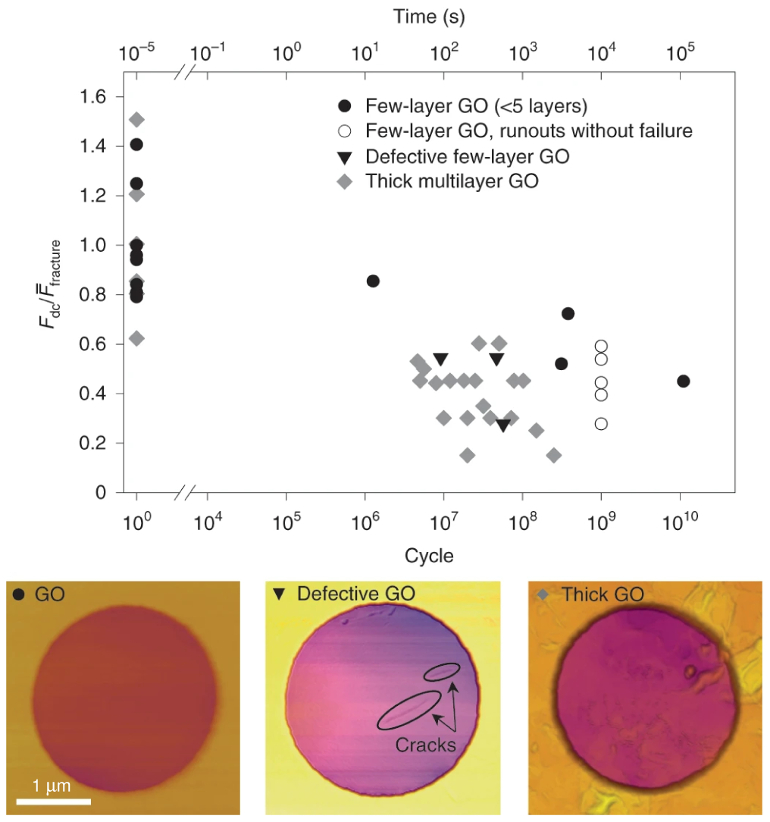

To that end, researchers at the University of Toronto and Rice University performed AFM-based fatigue testing and molecular dynamics simulations of freestanding graphene and graphene oxide sheets. Among the findings was a fatigue life of over one billion cycles for monolayer and few-layer graphene, higher than any material known. In contrast to the all-or-nothing failure observed in graphene, graphene oxide showed more conventional fatigue behavior with localized, progressive damage.

The results open the door to deeper investigation of mechanical reliability in 2D materials and suggest strategies to enhance their fatigue behavior for use in next-generation applications.

Fatigue testing was performed on the MFP-3D AFM. The experiments used a diamond AFM tip to cyclically deform 2D materials at 100 kHz with static loads between 20 and 85% of that required for fracture. The measurements used a customized procedure created with the open control software provided on all Asylum Research AFMs. Force curve measurements of elastic modulus and tapping mode images of topography and phase were also acquired intermittently throughout the testing for additional sample evaluation

Citation: T. Cui, S. Mukherjee, P. Sudeep et al., Fatigue of graphene. Nat. Mater. 19, 405 (2020). https://doi.org/10.1038/s41563-019-0586-y

Note: The data shown here are reused under fair use from the original article, which can be accessed through the article link above.