AFM Systems

AFM Accessories

Learning

Contact Us

Part of the Oxford Instruments Group

Part of the Oxford Instruments Group

Researchers demonstrated a nondestructive method for measuring the undercut of etched SiNx film structures. The approach used AFM nanomechanical techniques and had a theoretical measurement error of about 5%.

Etching processes used to fabricate microelectronic devices, MEMS, and other technology are prone to undercutting, where more material is removed than intended. Precise monitoring of undercut is therefore critical to ensure product specifications and performance. However, tools that are both nondestructive and provide high spatial resolution remain scarce.

Etching processes used to fabricate microelectronic devices, MEMS, and other technology are prone to undercutting, where more material is removed than intended. Precise monitoring of undercut is therefore critical to ensure product specifications and performance. However, tools that are both nondestructive and provide high spatial resolution remain scarce.

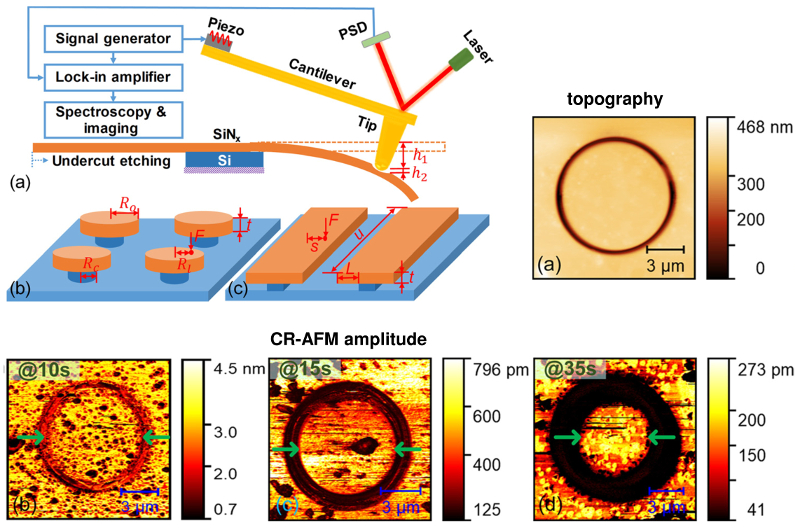

To this end, researchers at the University of Science and Technology of China in Hefei developed an AFM method to measure etch undercut on the nanoscale. Test structures were made by isotropically wet etching patterned thin films of silicon nitride (SiNx) on a silicon substrate to yield circular and rectangular center-supported plates.

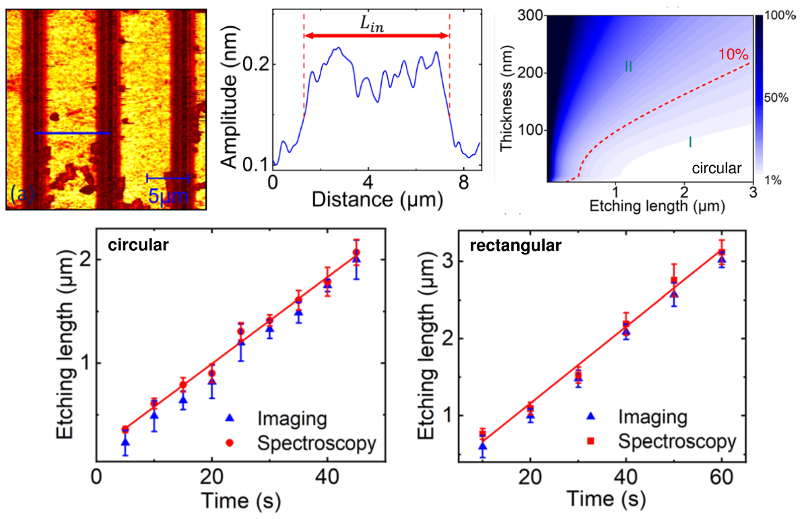

AFM nanomechanical images showed clear contrast between the suspended and supported areas and confirmed that undercut increased with etching duration. With these images, the researchers could identify undercut boundaries and measure undercut lengths. Etching rates were also determined from spectroscopic measurements and agreed with the imaging results. Theoretical analysis indicated a measurement error of about 5% with the experimental setup used.

The results suggest a strategy for in-situ, real-time detection of etch undercut at the nanoscale that could prove valuable in a variety of micro- and nanofabrication applications.

Experiments were performed on an MFP-3D Origin AFM with Contact Resonance Viscoelastic Mapping Mode (CR-AFM). The images above represent CR-AFM relative amplitude and have contrast related to mechanical contact stiffness. CR-AFM spectroscopy measurements of local resonant frequency were also made at selected sample positions. As these results illustrate, the Origin’s high functionality helps make it an exceptional research-grade AFM for its low cost.

Citation: W. Wang, C. Ma, and Y. Chen, Measurement of undercut etching by contact resonance atomic force microscopy. Appl. Phys. Lett. 117, 023103 (2020). https://doi.org/10.1063/5.0013479

Note: The data shown here are reused under fair use from the original article, which can be accessed through the article link above.

Author: Asylum Research

Category: Technical Article